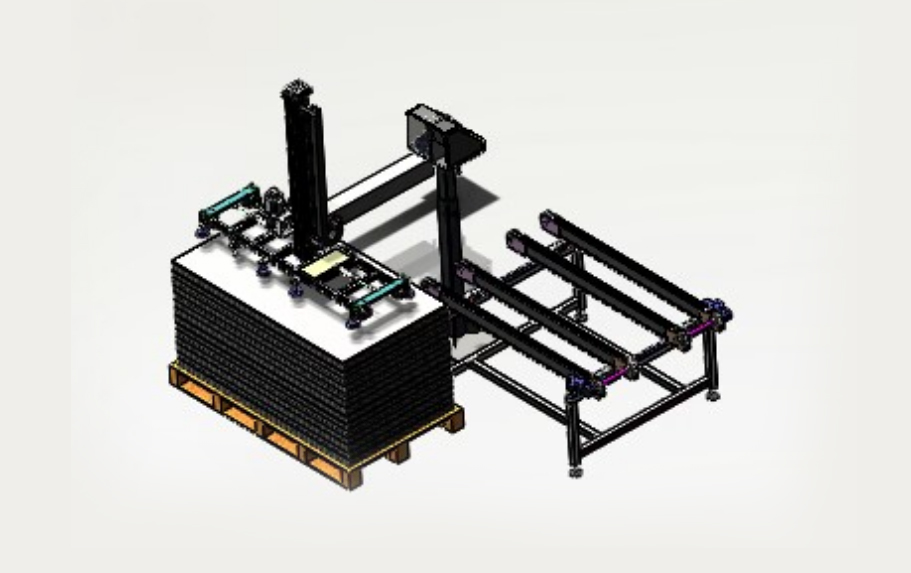

The scrapped components are transported to the loading station by forklift trucks, the panels are adsorbed by the rotating row frame z manipulator, rotated 90°, and then placed on the conveyor belt with the Z-axis downward to complete the positioning of the components; The conveying device feeds the positioned glass into the frame removal system. Beat 23s.

1. Device performance

1) Glass alignment accuracy: ≤±1mm

3) The equipment is fully automatic control, and the operation process does not require personnel operation;

2. Mechanical structure of equipment

1) The equipment adopts a complete set of gantry linear module, servo control, with fast, sensitive, accurate and other advantages;

2) Equipment main structure: steel structure + sheet metal;

6) Equipment composition: rack + lifting reversing line body ++ translation module + longitudinal moving module + up and down

Move module + Rotate

3. Motor control structure

1) Operation function: powerful man-machine interface, easy to understand parameter setting, fast and accurate product transformation;

4) Alarm function: three-color light indicator + sound report +HMI prompt, which can easily and quickly find the problem point of the equipment;

Overall dimensions 1800*1600*2200