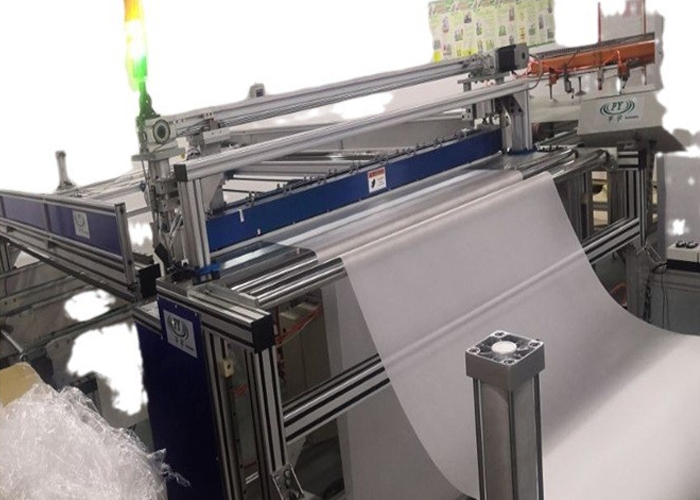

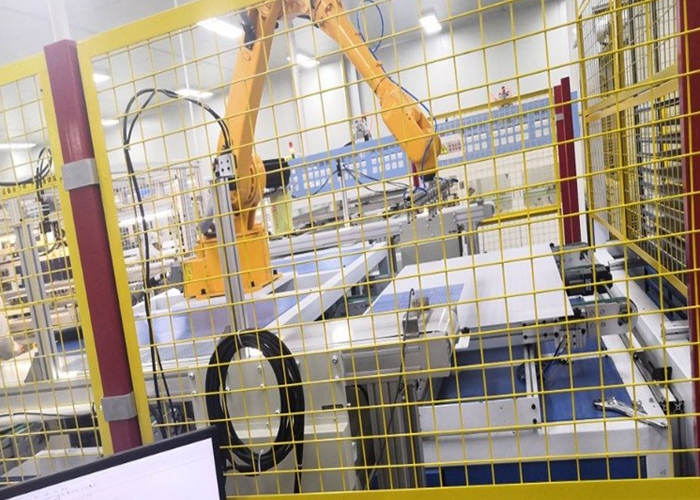

This production line is designed according to user needs, with transmission lines laid before lamination; The streamlined operation of component packaging process can be achieved through the transmission, transportation, direction change, positioning, rotation/release of different mechanisms, which can improve the production efficiency of unit components.

本生产线依据用户需求,进行“量身”设计,由层压前铺设传输线;通过不同机构的传输、转运、变向、定位、旋转/释放实现组件封装过程的流水化操作,可提高单位组件生产效率。

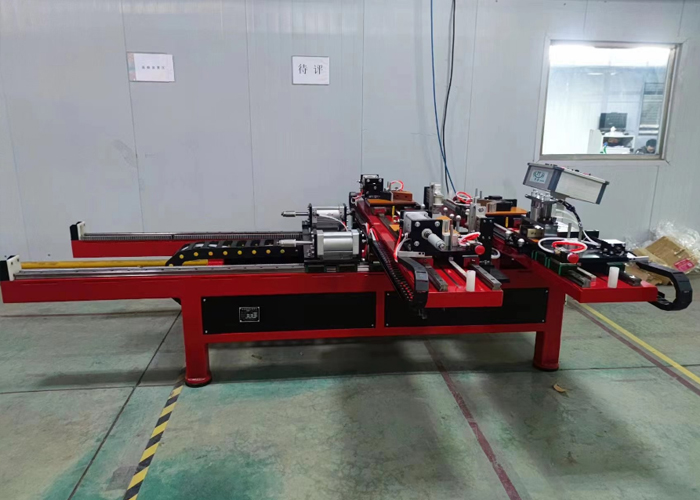

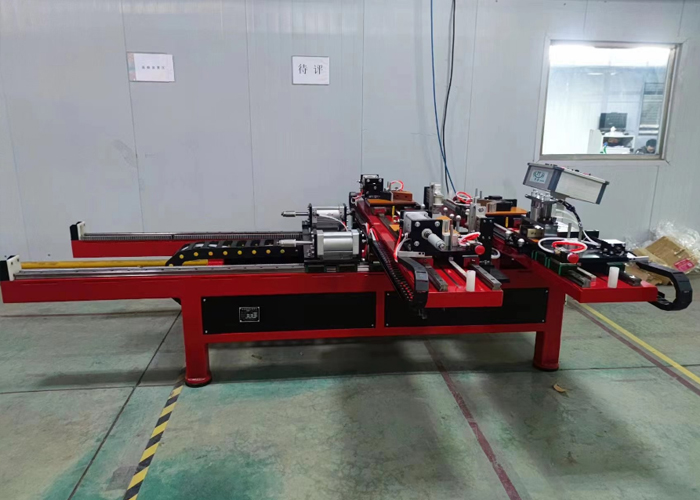

Changzhou Pingyu Automation Equipment specializes in manufacturing various non-standard customized framing machines, such as triangular, rectangular, and various irregular framing machines, with excellent quality. Good price, attentive service, the company's mission is to create value for customers. The fully automatic framing all-in-one machine is a specialized equipment for rectangular assembly of angle code willow joint aluminum alloy. Assembled from cylinders, linear guides, and steel structures, it can achieve extrusion and positioning of the aluminum alloy frame of the component after lamination.

A set of frames and aluminum alloy frames have been fixed on one device, simplifying the workload of workers, saving time, and improving product quality. Suitable for end faces of various profiles. Suitable for aluminum alloy frames with and without screws.

Changzhou Pingyu Automation Equipment specializes in manufacturing various non-standard customized framing machines, such as triangular, rectangular, and various irregular framing machines, with excellent quality. Good price, attentive service, the company's mission is to create value for customers. The fully automatic framing all-in-one machine is a specialized equipment for rectangular assembly of angle code willow joint aluminum alloy. Assembled from cylinders, linear guides, and steel structures, it can achieve extrusion and positioning of the aluminum alloy frame of the component after lamination.

A set of frames and aluminum alloy frames have been fixed on one device, simplifying the workload of workers, saving time, and improving product quality. Suitable for end faces of various profiles. Suitable for aluminum alloy frames with and without screws.

Changzhou Pingyu Automation Equipment Co., Ltd. is located in Jiangnan Ancient Town, a land of fish and rice, on the shore of Gehu Lake. The company has been engaged in the research and development and manufacturing of photovoltaic module automation production lines for many years. It is a comprehensive intelligent equipment manufacturer that integrates manufacturing, sales, and technical services. The products are widely used in industries such as forging, welding, machining, spraying, packaging, palletizing, etc. And has applied for multiple patents. We have good cooperation with large enterprises such as Changzhou Tianhe, Tianwei Yingli, Gree Air Conditioning, and Shangde.